Jolgeh Neishabour dairy factory with a history of 35 years of continuous production with international licenses and standards serves the society of Iran and the whole world. Now we are proud of our growing success and creating a new product line beyond the needs of the Iranian market and we are selling to markets outside of Iran all over the world.

Products

Big Jolgeh factory has the possibility to deliver your purchased products to dear traders in all parts of the world. Now we cooperate with large international transport companies.

Article

instant milk powder

It is a powdered form of milk that can be quickly reconstituted with water to produce liquid milk. This type of milk powder is usually used for convenience and long shelf life. The production process usually includes the following steps:

1. Milk collection and processing: Fresh milk is collected from dairy farms and processed to remove impurities and standardize the fat content.

2. Condensation: Milk is thickened to remove part of the water content, resulting in a thicker liquid.

3. Spray drying: The condensed milk is then sprayed into a heated chamber, where the remaining moisture evaporates quickly, leaving tiny milk particles.

4. Instantization: To create instant milk powder, milk powder particles are agglomerated or instantized, which improves their solubility in water and reduces clumping when reconstituted.

5. Packaging: Instant milk powder is packaged in sealed containers or bags to protect against moisture and oxidation and ensure a longer shelf life. Instant milk powder can be stored at room temperature and is suitable for use in a variety of applications, including as a substitute for fresh milk in cooking, baking and beverage preparation. Provides the nutritional benefits of milk in a convenient and easy-to-use form

"low-fat dry milk"

Low-fat dry milk is a type of dry milk with low fat content. This type of milk powder is primarily used by people looking to reduce fat intake or as part of a low-calorie diet. The production process of low-fat dry milk usually includes the following steps:

1. Milk collection and processing: Fresh milk is collected from dairy farms and processed to remove impurities and standardize the fat content.

2. Condensation: Milk is thickened to remove part of the water content, resulting in a thicker liquid.

3. Spray drying: The condensed milk is then sprayed into a heated chamber, where the remaining moisture evaporates quickly, leaving tiny milk particles.

4. Packaging: After drying, low-fat powdered milk is packed in suitable packaging materials that protect against moisture and oxidation and ensure a longer shelf life. Low-fat dry milk can be used in cooking, baking, making drinks and producing various protein products. Since it contains a lower percentage of fat, it is suitable for people who are following low-calorie diets or reducing their fat intake.

"Plant milk powder"

Plant milk powder is a milk substitute that is made from different plant sources such as almond, soy, oat or coconut. This type of milk is suitable for people who are lactose intolerant, vegetarian or looking for dairy-free options. The production process usually includes the following steps:

1. Selection of herbal ingredients: depending on the desired taste and nutritional characteristics, herbal ingredients such as almonds, soybeans, oats or coconuts are selected to prepare herbal milk.

2. Processing: Selected plant compounds are processed through methods such as steeping, grinding, and blending to extract a milky liquid.

3. Fortification (optional): To increase the nutritional value of plant milk, fortification with vitamins and minerals such as calcium, vitamin D and vitamin B12 may be added.

4. Spray drying (optional): In some cases, plant milk may undergo spray drying to remove excess moisture and create a powder form for convenience and long shelf life.

. 5. Packaging: plant-based milk powder is packed in closed containers or bags to preserve freshness and prevent contamination. Plant-based milk powder can be used as a substitute for traditional dairy milk in various culinary applications, including cooking, baking, and beverage preparation. It's a lactose-free, vegan-friendly alternative while providing essential nutrients and a creamy texture similar to dairy milk.

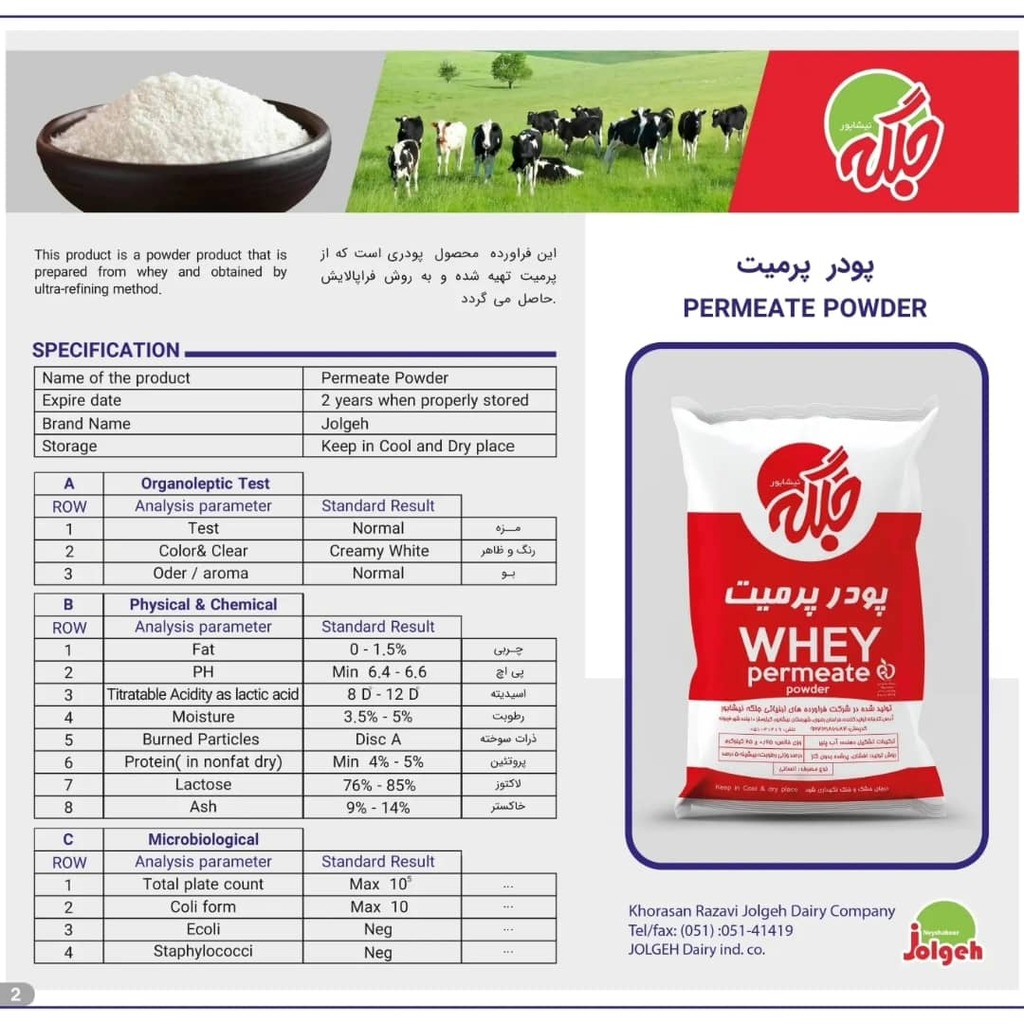

whey powder:

Whey powder is a powdered substance obtained from cheese and whey. This powder is used in various industries due to its nutritional properties and unique taste. In general, the production process of whey powder includes the following steps:

1. Whey Extraction: Whey, also known as whey cheese or whey, is obtained during the cheese making process. At this stage, the cheese becomes liquid and the whey is separated.

2. Purification and drying process: The whey is transferred to a purification facility to remove impurities and excess salts. Then, the purified whey is dried in drying machines to remove the maximum moisture, and as a result, it becomes a powder.

3. Packaging: After drying, the whey powder is packed in suitable packaging materials that protect it from air and moisture and increase the shelf life of the product. The use of whey powder is diverse and it is used in different industries such as food, bakery, beverage and protein products production. It has nutritional benefits and contributes to the taste of the final products.